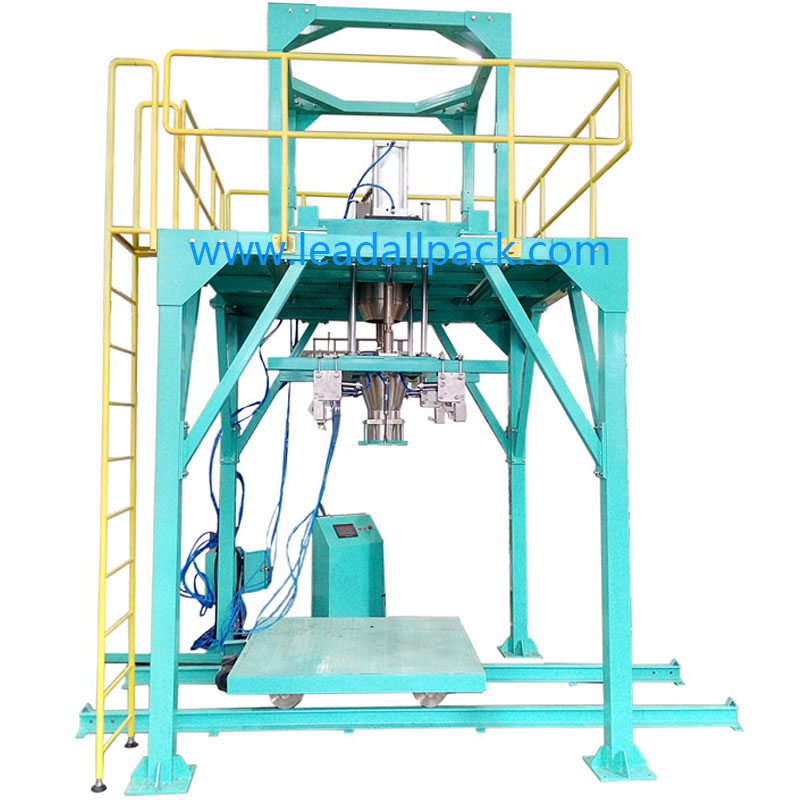

Bulk Bag Filler , Jumbo Bag Loading System manufacturer for 500kg to 1200kg Polyester Chips

Technical specification

| Machine Name | Bulk Bag Filler |

| Material range | 0.5-1.2ton |

| Packaging speed | 4-10 tons /hour |

| Accuracy | static accuracy 0.1%FA.OIMLⅢ grade, dynamic accuracy 0.3% |

| Powder Supply | AC380V |

| Air supply | 0.4-0.6 Mpa, 2 M3/H |

| Power | 2.5Kw |

| External dimension (LxWxH) | 5200x1800x3500mm |

application

| Granule | Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, Polyester Chips, Polyester Flakes, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules etc. |

| Powder | milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, chemical powder etc. |

automatic big bag filling machine, big bag loading, erkomat big bag, dumpy bag filler, bulk bag filler bucket, bulk bag filling system, what is a bulk bag weight, bulk bag filling stand, jumbo bag loading system, forklift bag filler, jumbo bag filling station, 1 ton bag filler, jumbo bag filling system, big bag loading system, big bag packaging machine, automated bulk bag filling, flexicon bulk bag filler, jumbo bag filling machine manufacturers, spiroflow bulk bag filler, bulka bag filler, bulk bag filling bucket, what weight is a jumbo bag, supersack filler, how much does a bulk bag of gravel weight, jumbo bag filler, bulk bag weighing, Jumbo Bag Loading System manufacturer & oem manufacturer, jumbo bagging system, bulk material handling equipment.

Advantages

1. The weighing system of CJD1000K quantification Ton packaging machinery contains high accuracy(0.2%) sensor and high resolution controller, to keep the machine with high accuracy and stable performance.

2. The material feeding parts adopt two kinds (big one and small one)valves to control the three kinds feeding: fast, slow and exactness.

3. The packing range is 0.5~1.2 ton adjustable. It suitable to big bags packing.

4 .The parameters setting and the weighing calibration is very simple and with convenient operation.

Construction Principle

1. Feeding part: Adopt two kinds(big one and small one)valves to control the three kinds feeding: fast, slow and exact mess.

2. Weighing shelf:The weighing shelf connected with sensor,and convey the weight signal to the electric box which controlling the operation of the machinery.

3. The electromotion car operated by the motor and run in the track to convey the products.The car’s position controlled by the worker and the final position is determined by the limit switch.

4. Electric box: Exterior signal and the sensor signal are conveyed to the electric box,which could control the feeding ON and OFF, cylinder lifting and the car running through finished program.

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4. What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.