PVC Resin Bulk Bag Filler , big filling machine for 500kg to 1000kg

application

Grains, Seeds, Grass Seeds, Bird Seed, Fish Feed, Flour, Rice, Corn, Soybeans, Barley, Animal Feed, Sugar, Salt, Spices & Seasonings, Milk Powder, Starch, Sodium Bi-Carbonate, Fertilizer, PVC Resin, Plastic Pellets, Carbon Black, Activated Carbon, Gypsum, Graphite, Barite, Bentonite, Limestone, Iron Oxide, Zinc Oxide, Titanium Dioxide, Mortar Mixes, Calcium Carbonate Powder.

Technical specification

| Name | bulk bag filler |

| Model | LADB-1000 |

| Metering Model | By Weighing |

| Feeding Model | ≤1000Kg |

| Accuracy | ±0.2~0.5% (Depends on product Character and Filling Speed) |

| Packing Speed | 10-20 bags/hour |

| Voltage | 3 Phase 415V, 50Hz, 6KW |

| Material | 304 Stainless Steel |

| Machine Weight | 3000Kg |

Features

1. Adopted by a fast,medium,slow feeding mode. AD processing technology of high speed, anti-interference technology, automatic error correction and compansation technology, accurate measurement, stable and reliable performance.

2. Adopted by a fast shear flow system and high precision weighing sensor to make sure that the measurement is very accurate, stable and reliable.

3. There have some intelligent functions, like weight display, cumulative bags,working display and fault alarm.

4. With RS232 and RS485 communication interface.

Machine Details

Dimension(L*W*H): According to requirement

Weight: 2500kg

After-sales Service Provided: Field installation, commissioning and training, Engineers available to service machinery overseas

Packing weight: 500-1000kg

Function: packing filling machine

Packing speed: 10-20bags/hour

Usage: chemical, machinery, mineral

Power: 5-11KW

Advantages

The materials of construction and build specifications of Jumbo Bag Packing Machine enable bulk material processing operations to run production at designed rates without concern for unplanned downtime, inaccurate filling, or excess labor costs common with under-performing big bag filling systems. This Jumbo Bag Packing Machine are engineered and constructed to withstand the harshest processing and packaging plant environments while providing exceptional performance in reliability and throughput.

jumbo bag filling machine, big bag filling, bulk bag filler, big bag filling machine, bulk bag filler hopper, big bag filling station, bulk bag filling frame, bulk bag filling equipment, bulk bag filling machine, big filling machine, used bulk bag filling bucket for sale, jumbo bag packing machine, bulk bag filling station, bulk bag fillers for sale, bigbag filling station, bulk bag filling frame for sale, bigbag filling system, big bag packing machine, tonne bag filler, big bag filling system, how much weight in a bulk bag, bulk bag filling bucket for sale, big packing machine, bulk filling machine.

FAQ

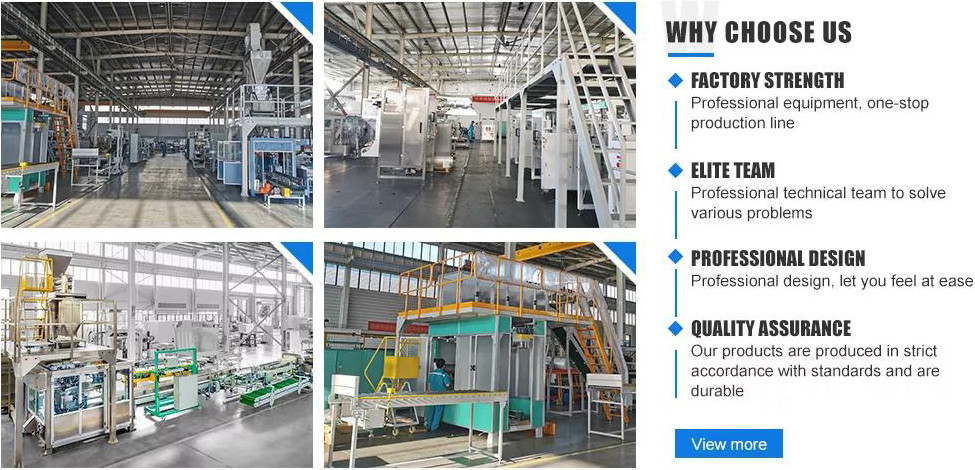

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4. What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.