Ton bag packaging machine , Bulk Bagging Systems for 500kg to 2000kg Plastic Pellets

Product description

Automatic Bulk Bag Filling Systems Suitable material and feeding method:

1) Gravity valve feeder ---for all kinds of granulars/ good fluent powder.

2) Screw feeder--for light powder.

3) Belt feeder--for block materials, or the moisture over 30% powder mix granular.

4) Rotatry Valve feeder--for fine powder with good fluent.

Automatic Bulk Bagging Systems Technical Parameters:

1) Weight range: 500kg ~ 2000kg.

2) Packing speed: 8-30 bag / hour (It depends on the material characteristics and net weight).

3) Packaging error: ≤± 0.2%.

4) Main engine power: Gravity flow feeding ≤ 2Kw , Spiral feeding ≤ 5Kw.

5) Power source: AC380V, 50Hz.

6) Working air pressure: 0.4 ~ 0.7MPa.

Main functions

Bag clamping and hanging apparatus function: After weighing is completed, the bag is automatically released from bag clamping and hanging apparatus.

Fast packaging speed and high precision.

Out-of-tolerance alarm function: if the packaging weight is no longer within the preset tolerance, an alarm indication will be output.

Automatic drop correction function: with the change of the material in the silo, the advance volume is automatically corrected to make the packaging accuracy more stable.

Automatic / manual function: It can be continuously packaged in automatic state, or it can be packed in jog mode using manual function.

Final counting function: it can record the quantity of finished packaging for each shift or every day.

Feeding method: Gravity flow feeding ; spiral feeding; vibration feeding; belt type feeding.

Option device:

vibration platform , air blowing function.

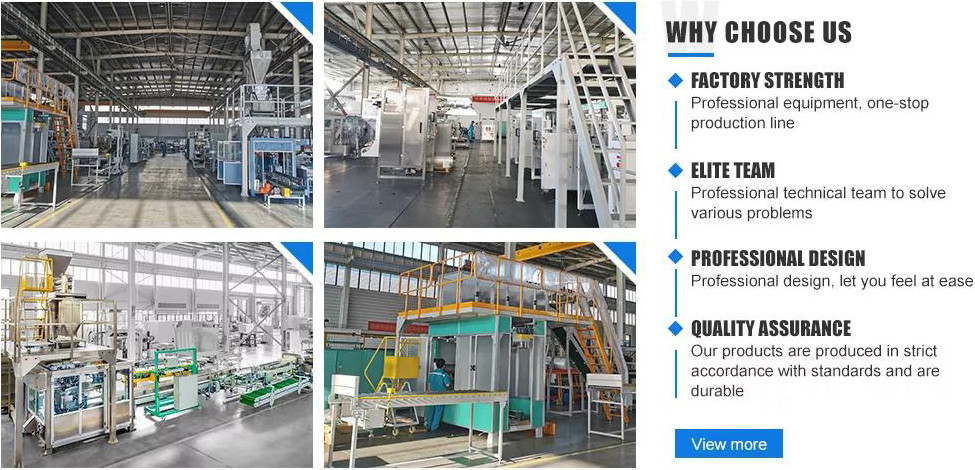

Our Advantage and why you choose us

Over 20 Years experience in Weighing Scale Field.

Own develop+manufacture+after sales service.

24 months quality assurance after machine ex factory.

Own technical on weighing controller , self-made programme, over 10 alarm code in weighing controller, can guide user find and solve the problems on quickest time based on the alarm code.

Provide machine all-life after sales service via online method.

Mechnical design usage period >10 years.

Weighing Controller design usage period >8 years

Use international brand pneumatic and electric parts to ensure the base quality and can replace on site easily.

Advantages

The materials of construction and build specifications of Bulk Bagging Systems enable bulk material processing operations to run production at designed rates without concern for unplanned downtime, inaccurate filling, or excess labor costs common with under-performing big bag filling systems. This Jumbo Bag Packing Machine are engineered and constructed to withstand the harshest processing and packaging plant environments while providing exceptional performance in reliability and throughput.

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4. What kind of Transportation could you provide? And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.