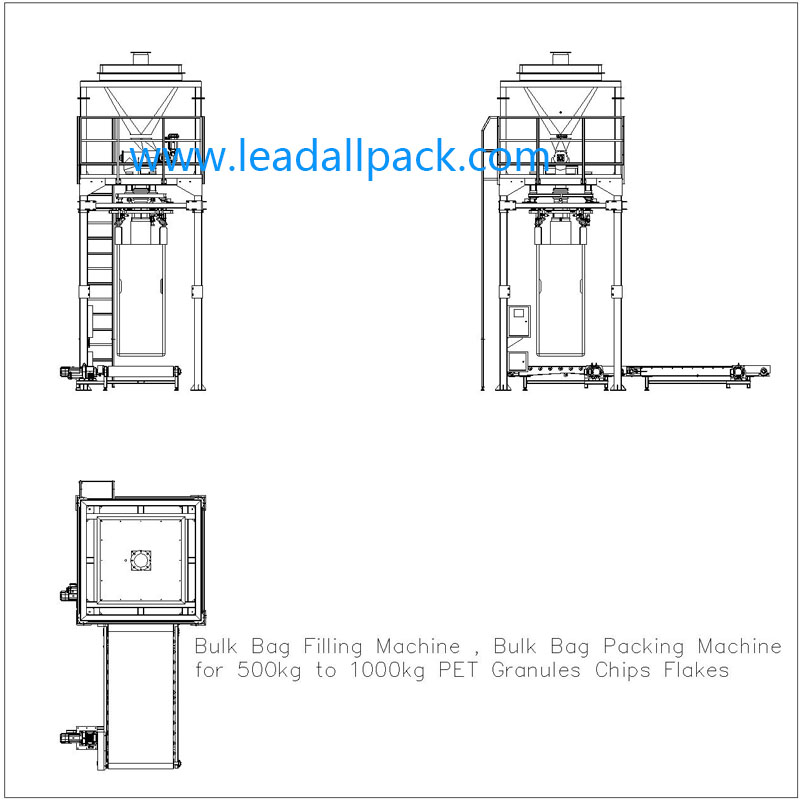

Refractory Material Bulk Bag Filling Systems , Tonne Bag Filler for 500kg to 1200kg

application

| Solid | candy, peanut, green bean, pistachio, brown sugar, cake, daily commodities, cooked food, pickles, puffed food etc. |

| Granule | grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts etc. |

| Powder | milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc. |

Working Flow

a). Manual hang ton bag on the mounting ear;

b). Manual press start button;

c). The products will free fall in the ton bag and detected by the load cell, when reach target weight, filling stop;

d). Manual take the bag down.

e). Electric trolly moves on the track back and forth and conveys packed products.

Technical Parameters

| Contact parts | SUS304 |

| Machine frame | Carbon steel with paint |

| Packing Form | Bulk bag |

| Packing weight | 500~1200kg |

| Accuracy | ±0.2% |

| Air Supply | 0.4-0.6Mpa |

| Air Consumption | 2m3/hour |

| Powder supply | AC380V,3P,50HZ,3KW |

| External dimension | L5200xW1800XH3500mm |

Configuration List

| NO | PRODUCT | BRAND | QTY |

| 1 | Weighing control part:

(1) Stainless steel scale (2) Stainless steel sensor (3) Stainless steel junction box (4) Weighing operating instrument (5) Erecting by overhang (6) Hanging cylinder (7) Electric control cabinet |

USA Mettler Toledo LEADALL PACK LEADALL PACK LEADALL PACK LEADALL PACK SMC LEADALL PACK |

1 4 1 1 1 4 1 |

| 2 | Feeding control part:

(1) Feed solenoid pilot actuated valve (2) Feed cylinder (3) Stainless feed door (4) Bag-clamped solenoid pilot actuated valve (5) Bag-clamped cylinder (6) Bag-clamped part (7) PLC |

SMC SMC LEADALL PACK LEADALL PACK SMC LEADALL PACK SIEMENS |

3 1 1 2 2 1 1 |

| 3 | Conveying control part:

(1) Stainless steel structural framing (2) Convey roller table (3) Reducing motor (4) Opto-electrical controlling system (5) Controlling cabinet |

LEADALL PACK LEADALL PACK CHINA OMRON LEADALL PACK |

1 1 1 1 1 |

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan)

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.