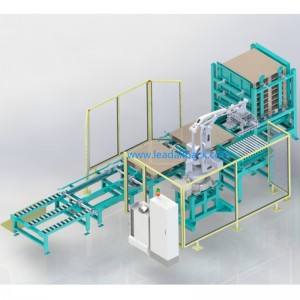

automatic pallet dispenser , automatic pallet magazine , Heavy Duty Pallet Dispenser for pallet stacking

Application

Pallet stackers/de-stackers provide an automatic method of dispensing or accumulating empty pallets into or removed from a conveyor system. recently added an economical stacker/destacker to its pallet handling conveyor product line. It is better to work with automatic palletizing line together for improving capacity.

Overview

This popular heavy duty pallet dispenser and collector is designed to handle the same size pallet in a stack up to five feet tall. A taller stack is possible with the twenty pallet magazine option. The machine will automatically dispense pallets in any of three directions, left, right, or straight ahead, from the bottom of the magazine at a rate of two pallets per minute. Pallets are loaded into one side of the magazine then discharged any other side. This is the most rugged pallet dispenser on the market and it is built to operate twenty four hours a day, seven days a week.

pallet magazine, automatic pallet magazine, pallet dispenser, automatic pallet dispenser, pallet dispenser machine, Automated pallet stacking, Pallet transport, empty pallet dispenser, pallet conveyor, pallet destacker, pallet roller, pallet conveyor system, pallet distribution, pallet roller conveyor, automatic pallet stacker, automated pallet stacker, pallet chain conveyor, bosch pallet conveyor, pallet conveyors automation systems, pallet transfer conveyor, gravity pallet conveyor, pallet conveyor manufacturers, powered pallet conveyor, pallet conveyor design, pallet handling conveyor, roller conveyor turntable, hytrol pallet conveyor, interroll pallet conveyor, pallet conveyor turntable, vertical pallet conveyor, heavy duty pallet conveyor systems, pallet roller conveyor systems, accumulating pallet conveyor, pallet lift conveyor, over under pallet conveyor, roller pallet conveyor, palletizer conveyor, pallet conveyor cost, auto pallet stacker, Heavy Duty Pallet Dispenser.

Technical specification

The automatic heavy duty pallet dispenser, will discharge a pallet out any one of three sides.

1) The air operated scissors lift has a 1600kgs capacity.

2) Two pair of pneumatic steel clamps pivot and hold up the stack.

3) The pivoting clamps are activated by heavy duty air bags.

4) Chain conveyor has two strands of 2060 chain.

5) Chain conveyor uses a 1/2 HP gear motor drive.

6) Dispenser is controlled by an Siemens PLC.

7) All necessary controls are in a NEMA 12 enclosure.

8) Body construction is 100mm square tubing, all welded structure.

9) All OSHA compliant safety guarding is provided.

10) This is a fully assembled, wired, piped, and tested machine.

11) The discharge rate is two pallets per minute.

12) Approximate size is, 2500mm tall x 1800mm wide x 1500mm deep.

Operation Description

This is a heavy duty, automatic pallet dispenser, built to operate 24/7.

1) A fork truck loads the magazine with a stack of pallets.

2) When called for, the stack is raised by an air operated scissors lift.

3) A pair of air-operated hands enter the second pallet in the stack.

4) The scissors lift lowers the bottom pallet while the remaining stack is held.

5) The scissors lift lowers between a two strand chain conveyor.

6) The pallet is left on the chains and conveyed out of the dispenser.

7) The remaining stack is then lowered and the cycle repeats.

Our Services

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan)

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4. What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.