Automatic Pet Food Baling Machine , Laundry Detergent Bag in Bag Vertical Bagging for LDPE Film Bag

This whole system includes

1) Horizontal belt conveyor for primary packaging machines (0.5~5kg pouch packaging machine).

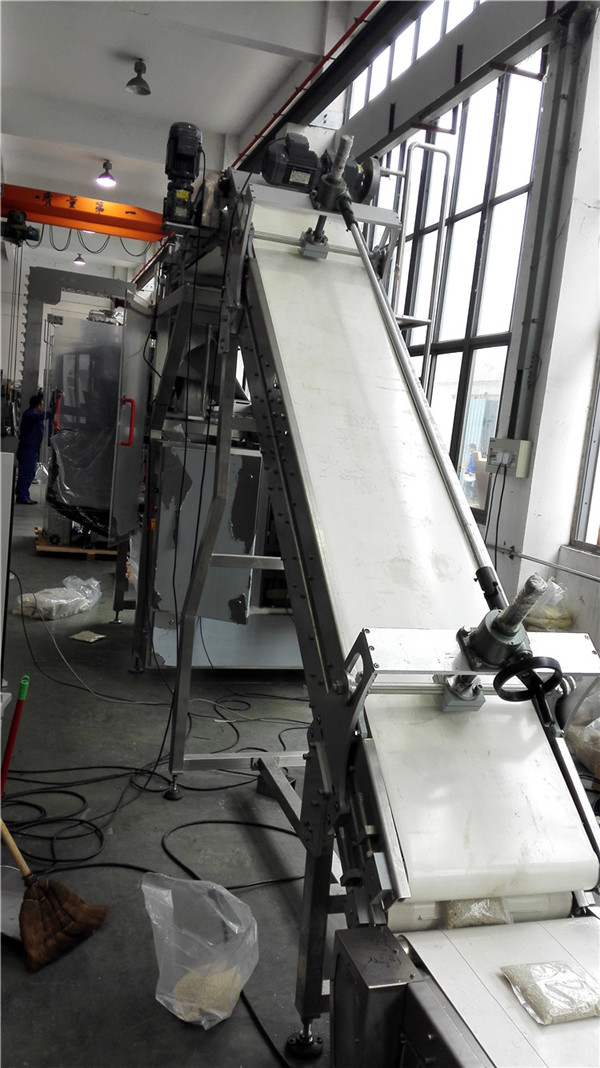

2) Slope arrangement belt conveyor.

3) Acceleration belt conveyor.

4) Counting and arranging machine.

5) LAP1300 bagging machine.

6) Take off conveyor belt one set.

Application

Granule : Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules, broken corn, corn, Raw whole peunut, Raw split peanut, blanched split peanut, blamched whole peanut, seeds virginhia ho kernel, inshel, corn, wheat, soy etc.

Powder : milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, chemical powder, corn flour, fine corn flour etc.

Details&Description

Automatic Bundling machine is used for secondary packaging of the primary bags. It uses the same Vertical Form Fill Seal principal and makes large bags of LDPE films. Usually placed after the primary VFFS machines to prepare bales/bundles of the primary bags in 1 or 2 columns with a maximum of 12 bags in a single column. Usual configuration is 24 bags of 1kg, 12 bags of 2kg and 5 bags of 5kg, since the max weight of the final bag can be up to 25kg only. The machine can realize up to 6-8 bagging cycles per minute and can handle up to 100 primary bags in a minute. Up to 2 primary machines can be connected to a single machine. Conveyors are provided so that this becomes a totally automated process with no manual intervention, thereby resulting in huge labor savings. The machine can substitute at least 4-5 labours which would otherwise be required in case of manual bundling operations. And still the uniform finishing and consistent speed levels achieved by the machine would be difficult to match.

Common applications include sugar, salt, flour, pasta and other such high-volume items.

General Specifications: Full automatic machine with CE certification. The compact design with electrical box. Very user-friendly PLC system, touch pad control panel. It is possible to synchronized with 2 automatic packaging machines with the production. To change the film roll and the forming set is very simple and fast. Easy to use and most of the function can be controlled on the PLC.

Bag in bag packing machine , Secondary packing, Rice bag packing machine, Bag baler , Bagging baler, Plastic bag baler, Baler bags, Machine baler, The baler, Secondary pack, Secondary packaging primary packaging and secondary packaging, primary packaging secondary packaging , Bag in Bag Vertical Bagging , Automatic Baling Machine , Automatic Bag In Bag Baler , Laundry Detergent Bag in Bag Vertical Bagging , Automatic Pet Food Baling Machine , Automatic Nuts Bag In Bag Baler .

Work Process

Slope arrangement conveyor will make the pouches flat before counting.

Acceleration belt conveyor will make the adjacent pouches leave enough distance for counting.

Counting and arranging machine will arrange the small pouches as required.

The small pouches will be loaded into the LAP1300 bagging machine.

LAP1300 bagging machine will seal and cut the big bag.

Belt conveyor will take the big bag under the LAP1300 machine.

Features

Automatic packing machine has functions of automatic lm pulling, bag making, filling, sealing.

Operation through touch screen. Convenient, safe and reliable.

Can meet requirements of different pouch arranging form.

Technical specification

|

Product Code |

LAP1300 |

|

Packing |

Polyethylene |

|

In-feed Speed |

100 pouches / min |

|

Maximum Weight |

25 kg |

|

Maximum Width |

630 mm |

|

Maximum Height |

700 mm |

|

Machine Width |

1823 mm |

|

Machine Depth |

1746 mm |

|

Machine height |

2764 mm |

|

Machine weight |

1100 kg |

|

Pneumatic system |

AirTac or SMC |

|

Electrical system |

7 kW - 3P - 380 V - 50 Hz |

|

Electrical consumption |

4 KW/h |

|

Electrical equipment |

Siemens |

|

PLC System |

Siemens |

|

Operating control panel |

Siemens |

|

Air pressure |

6-8 bar |

|

Air consumption |

5 lt/min |

|

Maximum film diameter |

500 mm |

|

Maximum film width |

1300 mm |

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan)

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.