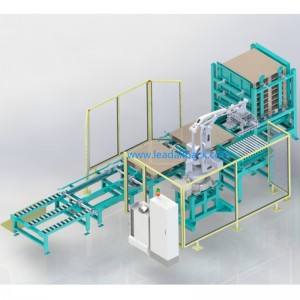

automated palletizing equipment , Robotic Bag Palletizer for 25kg 50kg Sugar bag

Description

Bag palletizing robots are widely used in the packaging machinery industry. It is a highly automated robotic arm that is a flexible palletizing system. The automatic palletizing robot machine is able to pick up the bags from the conveyor and place them in the designated palletizing position, following a pre-set palletizing shape.

The automatic robotic bag palletizer can handle bags from several input product lines simultaneously and enables the forward and backward feeds to be linked, reducing bagging time and greatly improving palletizing efficiency. The machine has a high level of accuracy and palletizing speed, all controlled via PLC. Automatic palletizers can shorten the length of the production line, allowing compact layouts, saving factory space, reducing the number of machines and making them easy to configure.

The robotic palletizing system is compatible with all common standard industrial pallets. It offers a wide range of flexibility and low maintenance. In addition to this, the palletizing robot is also able to perform unloading and stacking tasks for boxes, bundles, bins, cans, drums, trays, bottles, bags, etc. by modifying the program.

Robotic Gripper Options

In order to improve the adaptability of the automatic palletizing machines, we offer a customized service whereby the customer can custom different robotic grippers according to different needs of various industries.

Layout

Technical specification

| Item | Specification | |

| Name | Robotic Bag Palletizer , Bag Palletizer , Robotic Bag Palletizer , Robotic Case Palletizer , automated palletizing system, automated palletizer systems, automatic palletizer, automated palletizing, auto palletizing system, palletizer system, palletizing system, palletizing systems, robot palletising system, robot palletizer, palletizer robot, robot palletizing, robotic palletizing, robotic palletisers, Robotic Bag Palletizer, robotic palletizing system, palletizing automation, automated pallet system, pallet automation, jmp palletizing, auto palletizing machine, automatic palletizing machine, bag palletizing, fanuc palletizing robot, abb palletizing robot, kuka palletizing robot, fuji palletizing robot, kawasaki palletizing robot, yaskawa palletizing robot, semi automatic palletizer, Robot Palletizer Machine | |

| Controlled axis | 4 axis (A.B.C.D) | |

| Installation | Install on floor | |

| Motion Range | A(horizontal) | 1300mm |

| B(vertical) | 2100mm | |

| C(body) | 330° | |

| D(hand) | 330° | |

| Max. Load Capacity(contains hand) | 120Kg | |

| Handing Capacity | 1100 time/hour | |

| Drive capacity | AC servo motor drive | |

| Placement accuracy | ±0.5mm | |

| Power supply | 4.5KW | |

| Machine weight | 800Kg±10% | |

Including

Equipment basically consists of the horizontal conveyor, conveyor speed, counter manager charter, woven bags, automatic packaging machines, sewing machine, the product conveyor, Pallet dispenser, Palletizing robot.

Production process

Packaging materials ----to be weighing ----Automatic Vertical bag packaging machine pouch products ----Double standard conveyor speed inclined conveyor conveyor---- count charter management ---- bag automatic packing machine knitting sewing ---- bag output ----Palletizing.

Features

User-friendly operating panel with full touch screen operation, easy to use.

Simple mechanical construction, few parts, low failure rate and low maintenance costs.

Small size, small footprint, high flexibility, ability to change different types of jaws, high adaptability and save factory space.

Strong power, low energy consumption, low running noise and friendly environment.

Complete safety fences with one interlocked door.

Our Services

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan)

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4. What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.