slip sheet dispenser , pallet slip sheet dispenser , Automatic Slip Sheet Dispensers for slip sheet on pallet

Application

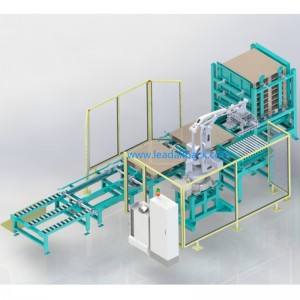

Robotic Palletizing Systems

Conventional Palletizing Systems

Slip Sheets

Tier Sheets

Bottom Sheet

How It Works

Slip sheets are loaded into a bin. A pneumatic or electrically driven gantry actuates to the pick point. A series of vacuum cups grab a single slip sheet. The gantry then moves to the drop point, the vacuum releases, and the slip sheet is placed into position. Configurations include standard dispensers, gantry dispensers, and robotic end of arm tools that for handling slip sheets.

slip sheet dispenser, pallet slip sheet dispenser, Automatic Slip Sheet Dispensers, slip sheet handling, slip sheet conveyor, slip sheet transport.

Benefits

- Can be used as part of fully-automated palletizing solution

- Reduces labor required for slip sheet handling

- Improves productivity by reducing cycle time

- Improves quality by placing slip sheet accurately every time

Technical parameters

Production Rate

- Dependent on palletizer

Dimensions - Pallet Magazine

- Length: 2559.1mm (100.75")

- Width: 1676.4mm (66")

- Height: 1521mm (59.88")

Power Requirements

- Input Power: N/A

- Control Circuit: 24 VDC

- Current Draw: N/A

Air Requirements

- Operating Pressure: 80 psi (5.4 atm)

- Line Pressure: 90 psi (6.1 atm)

- Air Use per Cycle: 5 cubic ft./cycle (141 liters)

Specifications

- Heavy duty fully welded construction

- Includes storage bin

- Nominal 24" x 24" slip sheets

- Up to 60" x 60" slip sheets

- Stand alone controls available

- Easily integrates into an existing palletizing system

Features

• Heady-duty construction and industrial-grade components add durability and dependability.

• Integrates with all palletizing systems with maximum efficiency.

• Complete changeover takes only a few minutes.

• Excellent ROI, often less than one year.

• Can be loaded while palletizer operates saving time and money.

Our Services

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan)

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4. What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.