bundle wrapping machine , secondary packaging solutions for Plastic bag baler

Product description

This is a complete secondary packing line, includes automatic dosing machine, primary vertical form fill seal machine, connecting conveyor, automatic pouch secondary packing machine, take-off conveyor, suitable for packing the small bags into big plastic bag in a certain order. It can be used for different kinds of granule or powder products when equipped with different dosing machine, such as: salt, sugar, rice, seasoning powder, etc.

Product application

Granule :

Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules etc.

Powder :

Milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, chemical powder etc.

Product Features

1. The front two sets automatic dosing machine own functions of weighing, filling.

2. The front two sets automatic primary vertical form fill seal machine own functions of bag-making, sealing, cutting, date printing, etc. used for packing bulk material in bags.

3. The connecting conveyor includes the converge conveyor to receive finished bags from primary vertical form fill seal machine and climbing conveyor to send bags to pouch secondary packing machine.

4. The pouch secondary packing machine own functions of bag dropping, bag-making, sealing, cutting, date printing, etc. used for packing primary packaging pouches into big plastic bag in a certain order.

5. all the primary vertical form fill seal machine and pouch secondary packing machine adopts international famous brand components, like Siemens PLC&touch screen, Omron temperature controller, Panasonic servo driver, Airtac/SMC pneumatic components, Schneider electrical components, etc. Works stable.

6. Minimize labor costs, improve packaging efficiency, and promote factory automation.

Detailed product specification

| Name | primary vertical form fill seal machine |

| Model | LA500 |

| Bags size | W:80~250mm L:50~340mm |

| Filling Volume (depending on type of products) |

100 – 1000g |

| Capacity (example: as seeds packing machine) | 40-45 bags/min |

| Fill motor | Servo motor |

| Packaging speed | 10--45 WPM |

| Hopper Capacity | 45L |

| Power supply | 380V 50HZ(60HZ) |

| Total Power | 1.4KW |

| Dimension(mm) | 530(L)*740(W)*910(H) |

| Name | pouch secondary packing machine |

| Model | LA-1100 |

| Pouch range | 100g~1kg |

| Secondary bag range | Max. 25kg |

| Bag Materials | Laminated film or LDPE film |

| Packing speed | 80~120 primary pouches/min |

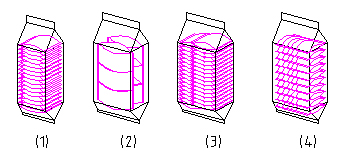

| Ranking form | single row laying/ double row laying/Three row laying |

| Compressed air | 0.4~0.6MPa |

| Power | 380V±10% 50Hz 20kw |