Semi-automatic Baling Machine , Secondary Packing Machine for 500g 1kg Sugar Salt Rice Pouch into Pp Woven Bags

Product description

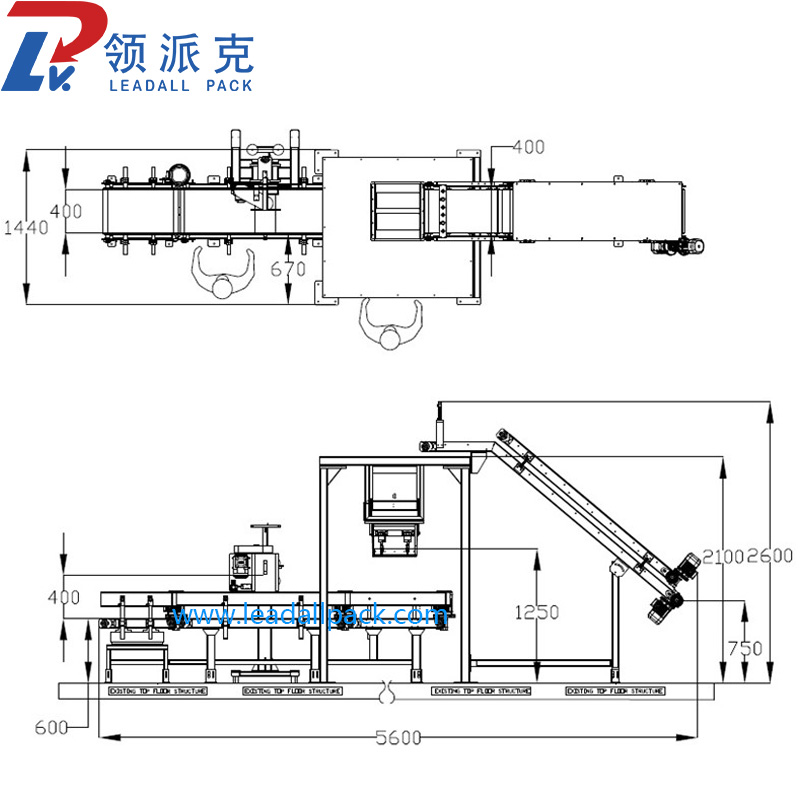

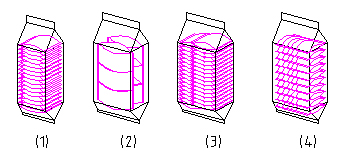

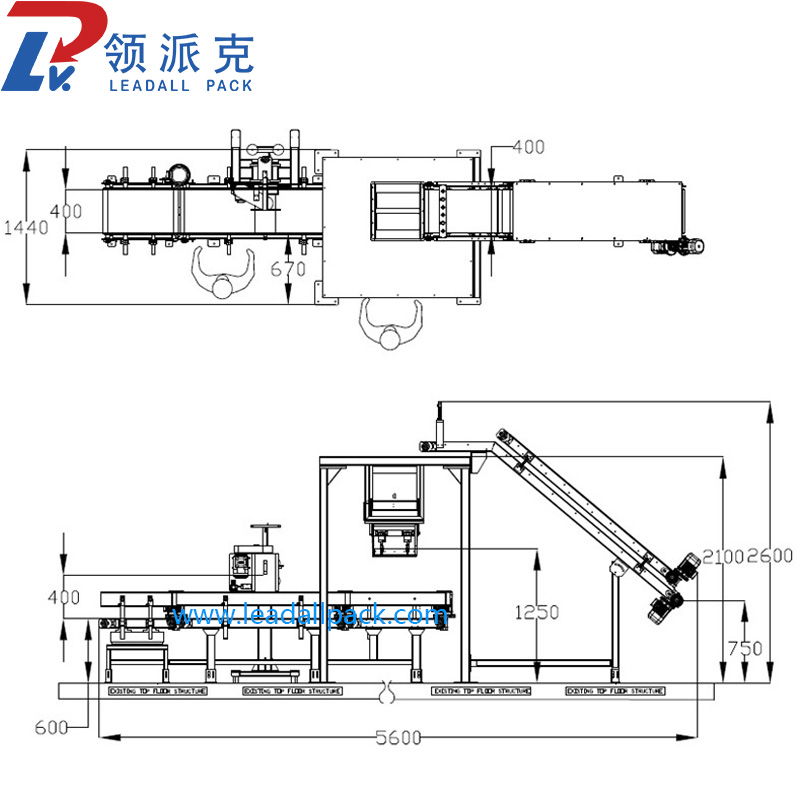

This is a complete secondary packing line, includes automatic dosing machine, primary vertical form fill seal machine, connecting conveyor, automatic pouch secondary packing machine, take-off conveyor, suitable for packing the small bags into big plastic bag in a certain order. It can be used for different kinds of granule or powder products when equipped with different dosing machine, such as: salt, sugar, rice, seasoning powder, etc.

Secondary packaging machine are the repacking of already packed products. This ensures that products are packed properly and therefore goods do not get spoiled or damaged. Packaging products well help in maintaining quality and standard as well as keeping count of the number of pouches.

If only part of the process requires automation then we can provide semi-automatic secondary packaging machines that can be designed according to your requirements.

application

| Granule | Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, Polyester Chips, Polyester Flakes, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules etc. |

| Powder | milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, chemical powder etc. |

Purpose

1) To pack pouches of grains and powders into pre-formed bags

2) To replace high cost baling

3) To overcomes manual and disorderly packaging

Features

1) Feeding the empty bags by manual, Auto-stich feeder.

2) Accurate Pouch Counter.

3) Accurate Weighing.

4) Metal Detector & Weighing Options Available.

5) Centralized Data Logging System.

Technical parameters

| Machine Speed | Up to 5-6 Bags / min |

| Types of bags | Pillow and Gusset Bags |

| Type of bag | Preformed Open Mouth, Paper Bags, HDPE Bags |

| Bag material | All types of Laminated bags, HDPE Bags |

| Bag width | 250 - 650 mm |

| Bag length | 500 - 1200 mm |

| Type of sealing | Thread Stitching / Heat Sealing |

| Filling | 10 - 50 kg |

advantage

1) Uses less space as compared to manual packaging.

2) Packaging becomes efficient and hence the productivity increases.

3) System can be aligned for further warehousing automation making the overall packaging and logistics not dependant on workforce.

4) Every bag produced is check for correctness in the pouch count & weight.

FAQ

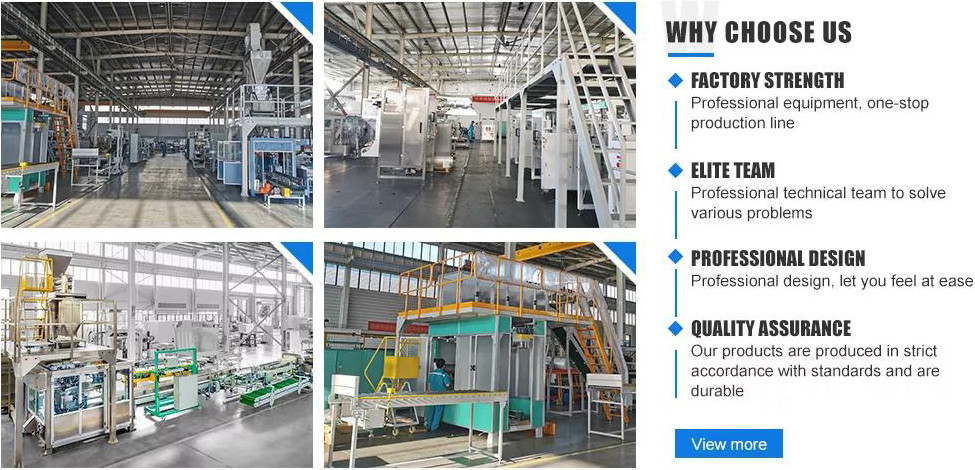

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.