Premade Pouch Filling Sealing Machine , Automatic Stand Up Pouch Packing Machine for 1kg refined white sugar

Equipment Layout

Application & Bag Type

Application:

It is suitable for weighing grain, stick, slice, globose, irregular shape products such as candy, chocolate, jelly, pasta, melon seeds, roasted seeds, peanuts, pistachios, almonds, cashews, nuts, coffee bean, chips, raisins, plum, cereals and other leisure foods, pet food, puffed food, vegetable, dehydrated vegetables, dry fruits, sea food, frozen food, small hardware, etc.

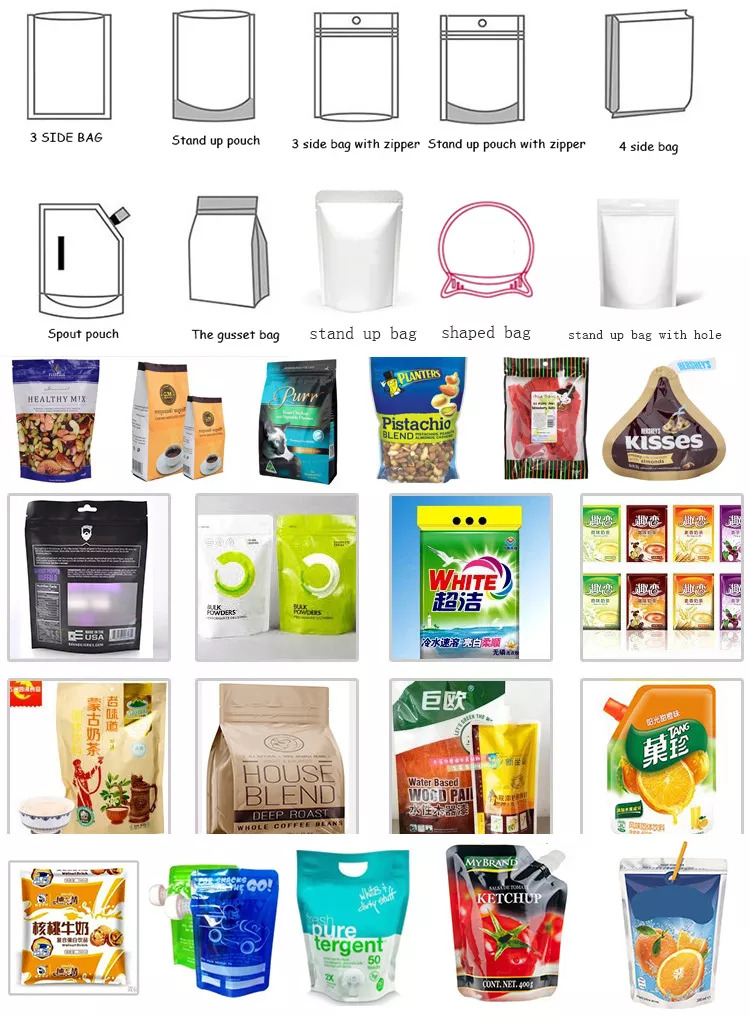

Bag Type:

Various bag types are available: All type of heat sealable performed side seal bags,block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout, paper bags etc.

Technical specification

| Name | Premade Pouch Filling Sealing Machine , Automatic Stand Up Pouch Packing Machine , Rotary Pouch Filling Machine , Doypack Pouch Filling Machine |

| Model | LA8-200/300 |

| Bag Size | Width: 80-210mm, Length:100-300mm;Width: 200-300mm, Length: 100-350mm; |

| Filling Volume | 5-2500g (Depending on type of products) |

| Capacity | 30-60bags/min (The speed depends on type of products and packaging material used)25-45bags/min (For zipper bag) |

| Package Accuracy | Error≤±1% |

| Total Power | 2.5KW (220V/380V,3PH,50HZ) |

| Dimension | 1710*1505*1640 (L*W*H) |

| Weight | 1480KGS |

| Compress Air Requirement | ≥0.8m³/min supply by user |

Safety Measures&Product Process

| Safety Measures | 1. no bag feeding, no filling and no sealing. 2. no bag opening/open error, no filling and no sealing 3. no filling, no sealing |

| Product Process | Station 1: Bag Feeding Station 2: Date Printing (option)and Open zipper bag Station 3: Open bag Station 4: Filling Materials Station 5,6,7: Vibration, Air Removal, Nitrogen Filling, Close Zipper, Hole Punching, Heat Sealing Remark: No.5.6.7.Stations are based on customer requirements for adjusting. Station 8: Heat Sealing and Product Output |

Technical Feature

1. Material conveying, weighing, filling, date-printing, finished product outputting are all completed automatically.

2. High weighing precision and efficiency and easy to operate.

3. Packaging and pattern will be perfect with pre-made bags and have the option of zipper bag.

System Construction

Z-type bucket elevator: Raise material to multi weigher which controls the start and stop of the hoister.

Multihead weighing machine: Used for quantitative weighing.

Supporting platform: Support the multiheads weigher.

8 Stations rotary packing machine: Pack the material with high speed. And data printed, seal and bag cut are completed.

Equipment Photos

Equipment Type

Rotary Bagger, Rotary Pouch Filling Machine, Doypack Sealing Machine, Doypack Filling And Sealing Machine, Stand Up Bag Filling Machine, Automatic Stand Up Pouch Packing Machine, Premade Pouch Filling Sealing Machine, Stand Up Pouch Filling Equipment, Stand Up Pouch Filling Machine, Zipper Pouch Machine, Doypack Pouch Filling Machine, Zipper Pouch Sealing Machine, Rotary Bagger, Automatic Bag Filling And Sealing Machine, Pouch Bag Packaging Machine, Seed Filling Machine, Pouchfill Packaging, Sugar Packing Machine Price, Pasta Packaging Machine, Coffee Packaging Factory, Snack Food Packaging Machine, Automatic Seed Packaging Machine, Beans Packing Machine Price, Nuts Filling Machine, Nuts Packing Machine Price, Fry Packaging Machinery, Small Weighing And Packing Machine, Sugar Pouch Packing Machine, Gusset Bag Packaging Machine, Automated Food Packaging Machine, Coffee Bagging Equipment, Coffee Packaging Machine, Coffee Filling Machine, Packaging Coffee Machine, Packaging Machine Distributor, Automatic Filling Packing Machine, 500 Gram Packing Machine, Beans Packaging Machine, Chocolate Pouch Packing Machine, Food Pouch Filling Machine, Plastic Pouch Packing Machine, Weight Packaging Machine, Rice Packaging Machine Price, Rotary Pouch Filling Machine, Sugar Packing Machine Video, Packaging Machinery Manufacturers Europe, Packaging Machine Drawing, Sugar Filling Machine, Quad Bag Packing Machine, Quad Seal Bag Packaging Machine, Salt Packaging Business, Detergent Powder Pouch Packing Machine, Detergent Powder Packing Machine Manufacturers, Detergent Packaging Machine, Sunflower Seed Packing Machine, Granule Bag Filler, Bag Filler, Screw Filling Machine, Rice Packing Machine, Salt Packing Machine, Sugar Packing Machine, Fill Seal Machine Factory, Gusset Bag Packaging Machine Exporter, sattu packing machine, besan packing, 5 kg atta packing machine, atta bag packing machine.

Our Services

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability.

We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan)

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.