New Arrival China Robotic Palletizing System - Robotic Bag Palletizer , Robot Palletizer Machine for 25kg 50kg pp woven bags kraft paper bag cases – Leadall

New Arrival China Robotic Palletizing System - Robotic Bag Palletizer , Robot Palletizer Machine for 25kg 50kg pp woven bags kraft paper bag cases – Leadall Detail:

Technical specification

Safer for workers.

Higher production rates.

Optimization of warehouse space.

Greater quality and stability of full pallet loads.

Quick payback on investment (savings on labor).

Minimal downtimes (maintenance, changeovers, repairs).

Greater competitiveness for your product in the market place.

More consistent production rates.

Low power consumption.

PLC controller, easy to use.

Technical specification

| Item | Specification | |

| Name | Robotic Bag Palletizer , Bag Palletizer , Robotic Bag Palletizer , Robotic Case Palletizer | |

| Controlled axis | 4 axis (A.B.C.D) | |

| Installation | Install on floor | |

|

Motion Range |

A(horizontal) | 1300mm |

| B(vertical) | 2100mm | |

| C(body) | 330° | |

| D(hand) | 330° | |

| Max. Load Capacity(contains hand) | 120Kg | |

| Handing Capacity | 1100 time/hour | |

| Drive capacity | AC servo motor drive | |

| Placement accuracy | ±0.5mm | |

| Power supply | 4.5KW | |

| Machine weight | 800Kg±10% | |

Including

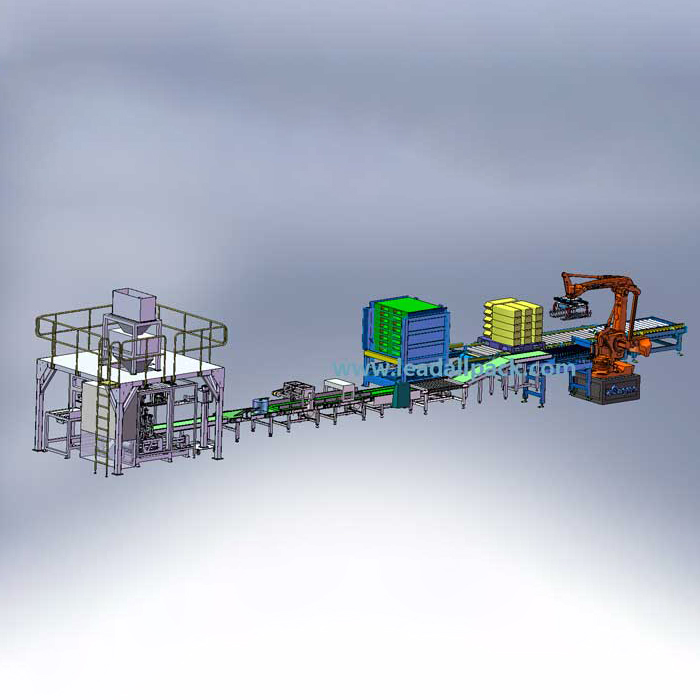

Equipment basically consists of the horizontal conveyor, conveyor speed, counter manager charter, woven bags, automatic packaging machines, sewing machine, the product conveyor, Palletizing robot.

Production process

packaging materials —-to be weighing —-Automatic Vertical bag packaging machine pouch products —-Double standard conveyor speed inclined conveyor conveyor—- count charter management —- bag automatic packing machine knitting sewing —- bag output —-Palletizing.

Characteristic

1.This machine adopts the computerized metering device, thus it can weigh&pack&palletize accurately, perform stably and be operated easily.

2. The body of this machine is completely sealed and also it is furnished with dedusting opening. Its structure is reasonable and durable and may realize environmental production in the true sense.

3. This machine is small in volume, low in weight and convenient for adjusting and maintaining; besides, thanks to its mechatronics, it can save electrical energy.

4. Weighing machine can be classified into impeller type and screw type according to their material discharging mode;

5. Wide application: This machine can be applied not only in the packaging of dry mortar but also in the packaging of other powder or particle materials, just as cement, dry mortar, fly ash, lime, calcium carbonate, talcum powder, gypsum, bentonite, kaolin, carbon black, alumina, fire materials powder, granule materials and so on.

Our Services

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

Product detail pictures:

Related Product Guide:

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for New Arrival China Robotic Palletizing System - Robotic Bag Palletizer , Robot Palletizer Machine for 25kg 50kg pp woven bags kraft paper bag cases – Leadall , The product will supply to all over the world, such as: Costa Rica, Poland, kazakhstan, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.