Good Quality Automated Bagging Line - sugar secondary packaging line , sugar secondary packaging line for 1kg pouch – Leadall

Good Quality Automated Bagging Line - sugar secondary packaging line , sugar secondary packaging line for 1kg pouch – Leadall Detail:

This line includes

Horizontal belt conveyor for primary packaging machines (0.5~5kg pouch packaging machine).

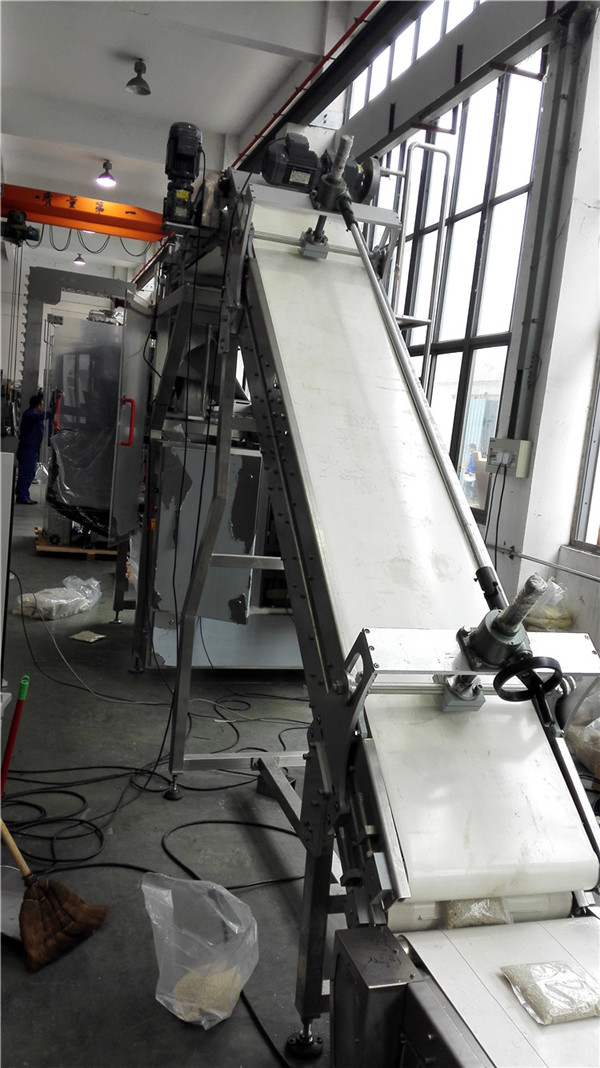

Slope arrangement belt conveyor.

Acceleration belt conveyor.

Counting and arranging machine.

LA1100 bagging machine.

Take off conveyor belt one set.

Work Process

Slope arrangement conveyor will make the pouches flat before counting.

Acceleration belt conveyor will make the adjacent pouches leave enough distance for counting.

Counting and arranging machine will arrange the small pouches as required.

The small pouches will be loaded into the LA1100 bagging machine.

LA1100 bagging machine will seal and cut the big bag.

Belt conveyor will take the big bag under the LA1100 machine.

Features

Automatic packing machine has functions of automatic lm pulling, bag making, filling, sealing.

Operation through touch screen. Convenient, safe and reliable.

Can meet requirements of different pouch arranging form.

Technical specification

| Machine Name | sugar secondary packaging line , sugar secondary packaging line |

| Product Code | LA1100 |

| Packing Range | 500g to 5000g per pouch |

| Packing Material | PE |

| Packing Speed |

4 ~ 10 big bags/min, ( 40 to 85 pouches/min) (speed slightly changes according to different products) |

| Ranking Form | single silo baiting, single or double row |

| Compressed Air Requirement | 0.4 to 0.6 MPa |

| Power Supply | 4.5KW 380V±10% 50Hz |

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Good Quality Automated Bagging Line - sugar secondary packaging line , sugar secondary packaging line for 1kg pouch – Leadall , The product will supply to all over the world, such as: Estonia, Slovakia, South Korea, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!