Excellent quality Semi Automatic Pouch Sealing Machine – Vertical form fill machine, vertical packaging machine – Leadall

Excellent quality Semi Automatic Pouch Sealing Machine – Vertical form fill machine, vertical packaging machine – Leadall Detail:

Application

Technical specification

| Name | vertical form fill machine , vertical packaging machine , Vffs Machine , Form Fill Seal Machine , Vffs Packaging Machine |

| Material | Carbon steel or SUS304 stainless steel |

| Bag-making size | L(50~340)× W(80~250) mm |

| Packing speed | 25-45bags/min |

| Compressed air requirement | 0.6Mpa, 350L/min |

| Power | 5.5KW |

| Bag Type | Pillow bag, gusset bag, punching bag |

| Bag material | LDPE, HDPE, PET, CPP etc |

| Machine weight | 700kg |

| Over all size | 1783*1217*1672mm L*W*H |

| Name | Standard 4 buckets weighing machine CJS2000-4 |

| Packaging speed | 15-30times/min |

| Power | 220V 50HZ 1.4KW |

| Dimension | 1840*700*1375mm L*W*H |

| Weighing bucket | 4L, 5.3L (optional) |

| Hopper capacity | 480L |

| Feature | Four-station independent weighing system, using upper and lower hoppers, stable weighing and high precision. 1. High-resolution single-point cantilever sensor with high sensitivity and more stable weighing. 2. Chinese and English touch screen operation interface, parameter settings are clear at a glance, and the operation is more user-friendly. A variety of different product parameters can be set to realize the selection of different products and measured values. The weighing bucket adopts the hanging installation method, which can be directly disassembled, which is convenient for machine maintenance. |

| Technical features | 1. This machine integrates the functions of bag making, filling, sealing, printing, punching and counting. 2. The film pulling adopts servo motor, which can automatically correct deviation. Horizontal sealing can be driven by cylinder and servo (convenient for customers to choose under different working conditions); longitudinal sealing mechanism has two types: middle sealing type and pressing plate type (users can choose according to specific materials and film rolls). 3. The machine has good sealing performance and can meet the hygienic requirements of customers. All electrical components and control components are well-known brands at home and abroad, with reliable performance; human-machine dialogue platform, operators and debugging personnel can set parameters through the touch screen. |

| Model | LA500 |

| Bags size | W:80~250mm L:50~340mm |

| Filling Volume(depending on type of products) | 100 – 1000g |

| Capacity(example: as seeds packing machine) | 40-45 bags/min |

| Fill motor | Servo motor |

| Packaging speed | 10–45 WPM |

| Hopper Capacity | 45L |

| Power supply | 380V 50HZ(60HZ) |

| Total Power | 1.4KW |

| Dimension(mm) | 530(L)*740(W)*910(H) |

| Model | LA-PD1500 |

| Material | Carbon steel or 304 stainless steel, PP belt |

| Size | Length: 1.5meter,Width: 0.3meter |

| Power | 0.375KW |

| Usage | Output conveying |

| Name | Standard 4 buckets weighing machine CJS2000-4 |

| Packaging speed | 15-30times/min |

| Power | 220V 50HZ 1.4KW |

| Dimension | 1840*700*1375mm L*W*H |

| Weighing bucket | 4L, 5.3L (optional) |

Our Services

1. The whole machine is guaranteed for one year, except for wearing parts;

2. 24-hour online email technical support;

3. Provide call service;

4. Provide user manual;

5. Lifetime reminder of wearing parts;

6. Provide installation guidance for domestic and foreign customers;

7. Provide maintenance and replacement services;

8. Technical staff training and guidance throughout the process.

Excellent after-sales service symbolizes our brand and competence. What we pursue is not only high-quality products, but also the best after-sales service. Your satisfaction is our ultimate goal.

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What are the advantages of your company?

A1. Our company has a professional technical and production team, as well as a professional production workshop and a complete production line.

Q2. Why should I choose your product?

A2. Our products are of high quality and low price.

Q3. What other good services can your company provide?

A3. We can provide good after-sales service and fast delivery, with a professional after-sales team to support technical services.

Q4. What kind of shipping can you provide? Can you update the production process information in time after placing the order?

A4. Sea, air and international express. After confirming your order, we will promptly send you emails and photos showing the production details of our products.

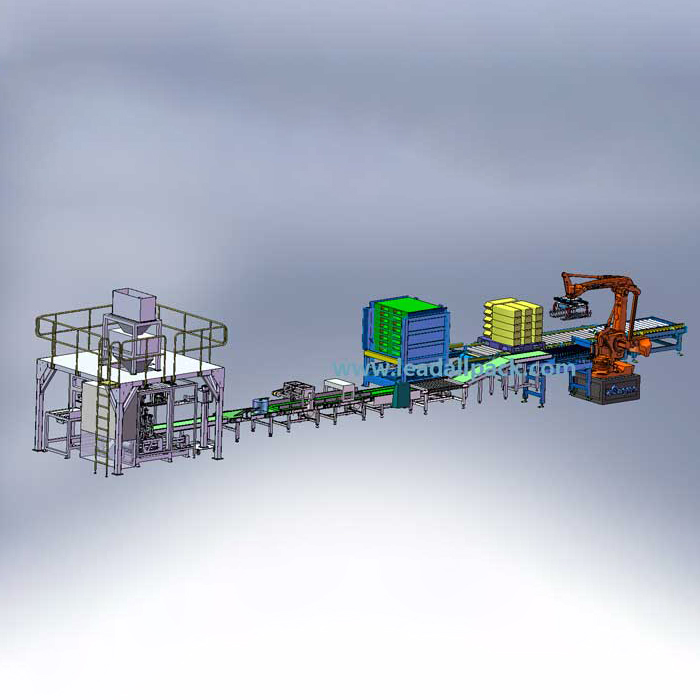

Product detail pictures:

Related Product Guide:

Adhering into the principle of "quality, provider, performance and growth", we now have gained trusts and praises from domestic and intercontinental consumer for Excellent quality Semi Automatic Pouch Sealing Machine – Vertical form fill machine, vertical packaging machine – Leadall , The product will supply to all over the world, such as: Lithuania, panama, Philippines, For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!