Chinese wholesale Bag Filling Machine - Sugar Open Mouth Bagging Machine for 25kg to 50kg Pp Woven Bag – Leadall

Chinese wholesale Bag Filling Machine - Sugar Open Mouth Bagging Machine for 25kg to 50kg Pp Woven Bag – Leadall Detail:

Technical specification

| Automatic granule open mouth bagging machine | |

| Item | Parameter |

| Pre-made bag | PP woven bags, Compound plastics film bag, paper bag etc. (the bag material can be assimilated by our bag feeding machine ) |

| Packaging speed | 5kg~10kg; (15-18 bags/min);10kg-25kg; (12-15 bags/min);

25kg~50kg; (8-12bags/min); |

| Filling weight range | 5-50KG |

| Power supply | 380V±10% 50Hz 6.5KW |

| Machine weight | 1400kg |

| Machine size | 6000*2000*4900mm |

| Air supply source | 0.6MPa, 0.5m3/min |

| Material | Carbon steel or SUS304 stainless steel |

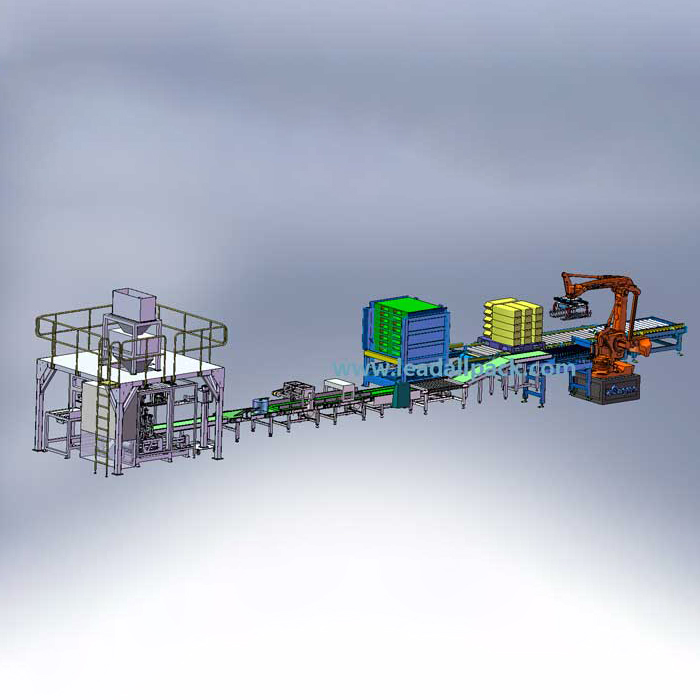

| Features | This packing unit includes one set of DT-2 bucket elevator (optional), one set of CJF50-S50 servo weighing, one set of granule heavy bag packaging machine, one set of GK35-6A sewing/sealing machine. |

| This machine integrates the functions of feeding, weighing, filling, bag-feeding, bag-opening, conveying, sealing/sewing, etc. | |

| The machine has good sealing performance and can meet customer’s hygienic requirements. | |

| All the electrical components and control components adopt local and foreign well-known brands with reliable performance, such as Siemens PLC and touch screen, Delta converter and servo motor, Schneider and Omron electrical components, etc. Man-machine dialogue platform, both the operator and debugging personnel can set parameters through the touch screen. | |

application

| Granule | Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, Polyester Chips, Polyester Flakes, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules etc. |

| Powder | milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, chemical powder etc. |

product

| Model | CJF50-S50 |

| Way of filling | Vibration |

| Packaging weight | Max.50kg |

| Weight accuracy | 0.5% ~1% |

| Fill motor | Servo motor |

| Packaging speed | 15~20time/min |

| Hopper Capacity | 150L |

| Power supply | 380V 50HZ(60HZ) |

| Total Power | 1.4KW |

| Dimension(mm) | 760(L)*800(W)*2000(H) |

| Model | DT2 bucket elevator |

| Material | Parts contact with material are made by s.s304, others are made by carbon steel with paint |

| Capacity | 3~6tons/hour |

| Height | 4~6m |

| Voltage | 220 volt, 50hz, 1phase |

| Power | 1.1KW |

| Features | 1. Storage hopper2. ABS food grade plastic buckets

easy to clean |

| Model | GK35-6A |

| Sewing speed | 2000r.p.m. |

| Maximum sewing thickness | 8mm |

| Stitch adjustment range | 6.5~11mm |

| Stitch pattern | Two-wire chain 401 |

| Sew specifications | Cotton thread, polyester thread lifting height of presser foot 11~16mm |

| Needle model | 80800×250#pulley diameter 114mm |

| Wire braid cutter device mechanical motor power | 370w |

| Machine weight | 30kg |

| Dimension(mm) | 50(L)*50(W)*1500(H) |

Packing

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for Chinese wholesale Bag Filling Machine - Sugar Open Mouth Bagging Machine for 25kg to 50kg Pp Woven Bag – Leadall , The product will supply to all over the world, such as: Ottawa, Latvia, Casablanca, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.