China Cheap price Forklift Bag Filler - Plastic Pellets Bulk Bagging Systems for 500kg to 2000kg – Leadall

China Cheap price Forklift Bag Filler - Plastic Pellets Bulk Bagging Systems for 500kg to 2000kg – Leadall Detail:

Product description

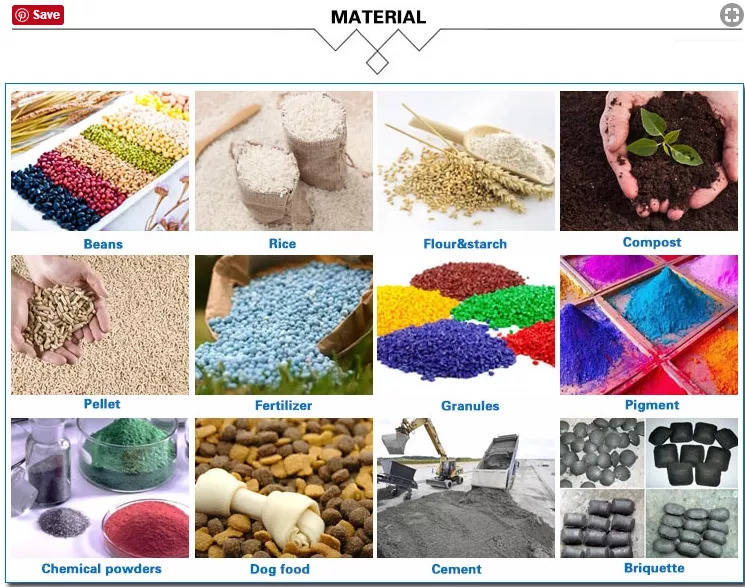

Automatic Bulk Bag Filling Systems Suitable material and feeding method:

1)Gravity valve feeder —for all kinds of granulars/ good fluent powder.

2)Screw feeder–for light powder.

3)Belt feeder–for block materials, or the moisture over 30% powder mix granular.

4)Rotatry Valve feeder–for fine powder with good fluent.

Automatic Bulk Bagging Systems Technical Parameters:

1)Weight range: 500kg ~ 2000kg;

2)Packing speed: 8-30 bag / hour (It depends on the material characteristics and net weight);

3)Packaging error: ≤± 0.2%;

4)Main engine power: Gravity flow feeding ≤ 2KW , Spiral feeding ≤ 5kW;

5)Power source: AC380V, 50Hz;

6)Working air pressure: 0.4 ~ 0.7MPa;

application

Bulk Bagging Systems is suitable for quantitative packaging of powder and granular materials in bulk bags. It widely used in food, chemical, engineering plastics, fertilizer, feed, building materials and other industries.

Main functions

Bag clamping and hanging apparatus function: After weighing is completed, the bag is automatically released from bag clamping and hanging apparatus.

Fast packaging speed and high precision.

Out-of-tolerance alarm function: if the packaging weight is no longer within the preset tolerance, an alarm indication will be output.

Automatic drop correction function: with the change of the material in the silo, the advance volume is automatically corrected to make the packaging accuracy more stable.

Automatic / manual function: It can be continuously packaged in automatic state, or it can be packed in jog mode using manual function.

Final counting function: it can record the quantity of finished packaging for each shift or every day.

Feeding method: Gravity flow feeding ; spiral feeding; vibration feeding; belt type feeding;

Option device:

vibration platform , air blowing function.

Our Advantage and why you choose us

Over 20 Years experience in Weighing Scale Field.

Own develop+manufacture+after sales service.

24 months quality assurance after machine ex factory.

Own technical on weighing controller , self-made programme, over 10 alarm code in weighing controller, can guide user find and solve the problems on quickest time based on the alarm code.

Provide machine all-life after sales service via online method.

Mechnical design usage period >10 years.

Weighing Controller design usage period >8 years

Use international brand pneumatic and electric parts to ensure the base quality and can replace on site easily.

Advantages

The materials of construction and build specifications of Bulk Bagging Systems enable bulk material processing operations to run production at designed rates without concern for unplanned downtime, inaccurate filling, or excess labor costs common with under-performing big bag filling systems. This Jumbo Bag Packing Machine are engineered and constructed to withstand the harshest processing and packaging plant environments while providing exceptional performance in reliability and throughput.

application

Other optional device

Packing

Product detail pictures:

Related Product Guide:

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for China Cheap price Forklift Bag Filler - Plastic Pellets Bulk Bagging Systems for 500kg to 2000kg – Leadall , The product will supply to all over the world, such as: Malaysia, Roman, London, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.