20kg to 50kg Open Mouth Bagging Machine , Thailand sugar bagging machine , Mitr Phol Sugar bagging machine for Sugar , Corn

Application & Packaging Bags

Granule material: Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules, broken corn, corn, Refined white sugar, Prime Fresh Salt, Additive products, degerminated broken corn, PET flakes, PET chips, PET granules, PET particle, etc.

Whole Introduction for system

1. The system is suitable for paper bags, woven bags,plastic bags and other packaging materials, widely used in chemical industry, feed, food ,fertilizer and other industries.

2. Can be suitable for 20-50kg bag packaging, with up to max 900bags/hour capacity.

3. Automatic bag device adapt to high-speed continuous operation.

4. The execution unites are equipped with control and safety devices, automatic continuous operation.

5. Using SEW motor drive unite can play higher performance.

6. Proposed matching KS series heat sealing machine work to ensure beautifual bag, anti-leakage, airtight.

Main Structures

1. Auto bag placing

2. Auto filling system

3. Auto weighing balance

4. Auto bag filled

5. Auto bag sealed

6. Electric control cabinet

Technical specification

| Equipment Name | Open mouth bagging machine |

| Bagging weight range | 20-50kg |

| Packing speed | 7-12bags/min |

| Bag Material&Bag Size | PP woven bag with or without Inner lining bag, Kraft paper bag, Plastic bag; Bag Width: 400-500mm; Bag length: 750-950mm. |

| Air consumption | 1Mpa |

| Gas consumption | 2m³/min |

| Power voltage | 220VAC/380 three phase/50HZ |

| Power supply | 8Kw |

Automatic packing machine process

1. Automatic for the bags-->2 aligned horizontally opposed bags disk can store about 200 empty bags( storage capacity due to the thickness of the air bag varies), take the bags from the suction cup device to a device for bags. When the empty bag after taking a unit, set the bag tray next unit automatically switches to take the bag position to ensure continuous operation of the device.

2. Bag--bit integer-->to adjust the overall position of the bag.

3. Empty bag extraction-->extraction bag bit plastic plate over the bag.

4. Lateral movement-->empty bag gripped by the clip below spout body bags, cutting open the door into the pouch feed.

5. Empty bag open-->empty bag after moving to the feed opening position, open the bag by the vacuum suction.

6.Bag feeding device-->empty bag gripped by the clip below spout body bags, cutting open the door into the pouch feed.

7. Transition hopper+secondary materials door-->hopper for the transition section between the weighing machine and packaging machines, the main function of the secondary material is next door from the slow process of material action to reduce air content material.

8. After the bag bottom slap device-->filling material, this means slap bottom of the bag, so that the bag material fully implemented.

9. Solid lateral movement and the bag holding the bag inductions-->real bags from the spout to put on stand -up pouches conveyor, by the bag holding means holding the bag delivered to the sealing.

10. Stand-up pouches conveyor-->real bags whereby the conveyor at a constant speed of delivery to the downstream, height--adjustable handle height adjustable conveyor.

11. Transition conveyor-->with different device height of perfect butt.

Advantage

1. Dual Hopper Weighing System-- with Mettler Toledo Brand Load Cell.

2. Use France Schneider brand electric parts.

3. Use Taiwan or Japan or Germany pneumatic parts.

4. Provide all life online after sales service.

5. Machine designed and manufactured based on 8 years+ life.

6. Fully automatic type, no need labor.

7. animal feed bagging, animal feed bagging machine, automated packaging systems, bag filling machine, 25kg sugar bagging, 25kg sugar bagging machine, bag packing machine, refined sugar 50kg bagging machine, polythene bag, pp woven bag bagging machine, Thailand sugar bagging machine, raw sugar bagging machine, Brazil sugar bagging machine, 50kg bags packing machine, big bag packing machine, 25kg bag packaging machinery, Automatic 50kg pp woven kraft paper bag packing machine, 50kg bags packing machine, pp woven bag packing machine, kraft paper bag packing machine, 25 kg rice packing machine, 25kg rice bag packing machine, 25kg sugar pp woven bag packing machine, 25kg corn bag packing machine, 25kg mixed corn packing machine, pp bag packing machine, powder sugar packing machine, sugar packing, sugar packing machine, granulated sugar bagging machine, sugar bagging machine, white sugar bagging machine, refined sugar packing machine, granulated sugar packing machine, 25kg sugar packing machine, Mitr Phol Sugar bagging machine.

Main Products

Main Product: 25 kg rice packing machine, 25kg bag packaging machinery, 25kg corn bag packing machine, 25kg mixed corn packing machine, 25kg rice bag packing machine, 25kg sugar bagging, 25kg sugar bagging machine, 25kg sugar packing machine, 25kg sugar pp woven bag packing machine, 50kg bags packing machine, animal feed bagging, animal feed bagging machine, automated packaging systems, Automatic 50kg pp woven kraft paper bag packing machine, automatic packaging machine, Bag Filling Machine, bag packing machine, bagging equipment, bagging machine for open mouth bag, Bagging System, big bag packing machine, Brazil sugar bagging machine, granulated sugar bagging machine, granulated sugar packing machine, intelligent packaging machine, kraft paper bag packing machine, Mitr Phol Sugar bagging machine, Open Mouth Bag Filler, open mouth bag packaging machine, Open Mouth Bag Packing Machine, open mouth bagging equipment, polythene bag, powder sugar packing machine, pp bag packing machine, pp woven bag bagging machine, pp woven bag packing machine, raw sugar bagging machine, refined sugar 50kg bagging machine, refined sugar packing machine, sandbag filling, sandbag filling machine, sugar bagging machine, sugar packing, sugar packing machine, Thailand sugar bagging machine, white sugar bagging machine

FAQ

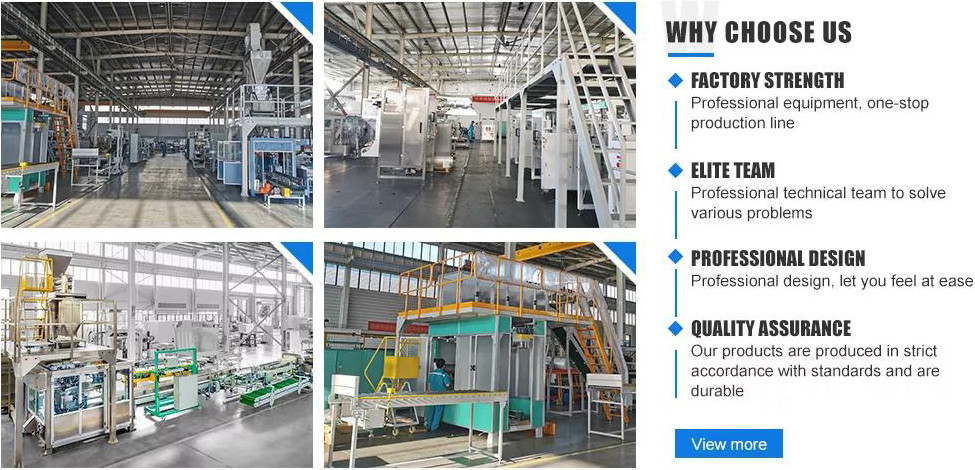

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4. What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order, we would keep you updated of production details of emails and photos.