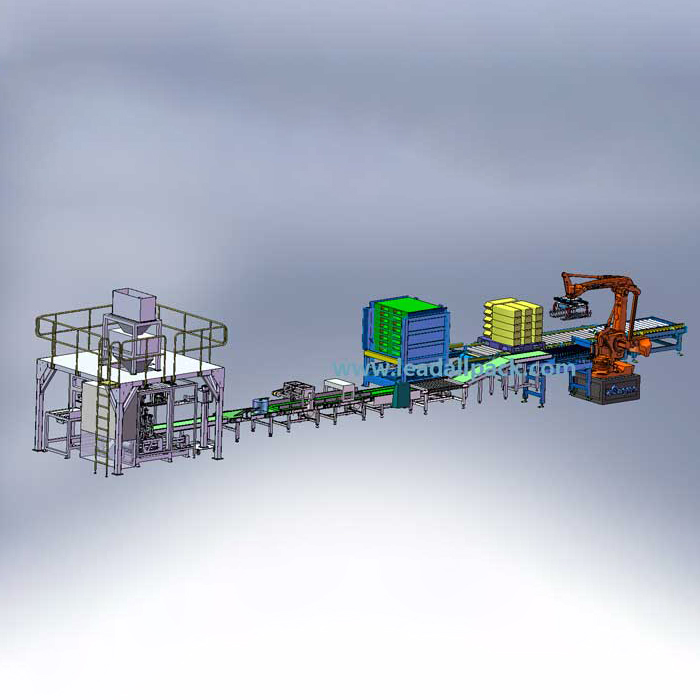

2022 Good Quality Hopper Bagging Machine - open mouth bagging system , Bagging System for 20kg to 50kg – Leadall

2022 Good Quality Hopper Bagging Machine - open mouth bagging system , Bagging System for 20kg to 50kg – Leadall Detail:

detail picture

Technical specification

| Name | open mouth bagging system , Bagging System , Open Mouth Bagging Scale , Automated Bag Packaging Machinery , Material Packing Machine , 50 Kg Bagging Machine , Sack Filling Machine |

| Bagging weight range | 20-50kg |

| Packing speed | 8-13ags/min |

| Bag Material | width:400-520mm; length: 550-950mm |

| Air consumption | 1Mpa |

| Gas consumption | 3m³/min |

| Power voltage | 220VAC/380 three phase/50HZ |

| Power | 8Kw |

Main Structures

1. Auto bag placing

2. Auto filling system (belt feeder)

3. Auto weighting balance

4. Auto bag filled

5. Auto bag sealed or Sewed

6. Electric control cabinet

7. Re-weight checking Machine

8. Kick off machine

9. Vibration bag device

10. Palletizing Robot

Working Process

1. Pre-place Empty Bags

Place 2~3 stacks of empty bags at the same time to provide bags for the packaging machine.

2.Take an Empty bag

The bag sucking mechanism sucks the bottom of the bag with negative pressure, while the roller-up type bag transmission structure flattens the bag mouth and transmits it to the bag opening station.

3.Open Empty bag

The bag opening mechanism simultaneously sucks the positive and negative sides of the bag mouth with negative pressure. The negative pressure sucks the bag mouth and lifts it, and then the “insert knives” structure located on both sides of the material discharge port is inserted into the bag mouth by shaft rotation and spread to both sides.

4.Supply Empty bag

Transfer the empty bag to the bag clamping mechanism by lifting up the knife arm to complete the bag supplying operation. The bag clamping mechanism clamps both sides of the bag to prevent dust from overflowing.

5.Material Filling

The bag clamping detection device ensures the reliability of the bag supplying. After the detection is completed, the PLC will give a signal to the automatic weighing unit, then the material in the weighing unit will be discharged into the packaging bag. During the filling process, perform bottom vibration operation. At the same time, through the external dust removal interface, the dust formed by the material is pumped away in the discharge process.

6.Holding bag and Stitching Sewing & Heat Sealing

After the material filling is completed, the bag mouth is clamped horizontally through the bag-holding conveying mechanism, then the bag is horizontally conveyed to the guide entry mechanism, and the bag is conveyed to the stitching sewing & heat sealing station for automatic stitching sewing or heat sealing.

Product Characteristics

Easy to operate and use

Bag-clamp equipment is advanced, material can be fully filled

Fill material system has material-stop equipment, accuracy high

Control, work parts all use imported parts, stable and reliable with sewing machine

Heat-sealing machine optional

Our Services

1. one year guarantee for whole machine except for wear parts;

2. 24 hours technical support by email;

3. calling service;

4. user manual available;

5. reminding for the service life of the wearing parts;

6. installation guide for clients from both China and abroad;

7. maintenance and replacement service;

8. whole process training and guidance from our technicians. High quality of after-sales service symbolizes our brand and ability. We pursue not only good quality products, but also best after sales service. Your satisfaction is our final purpose.

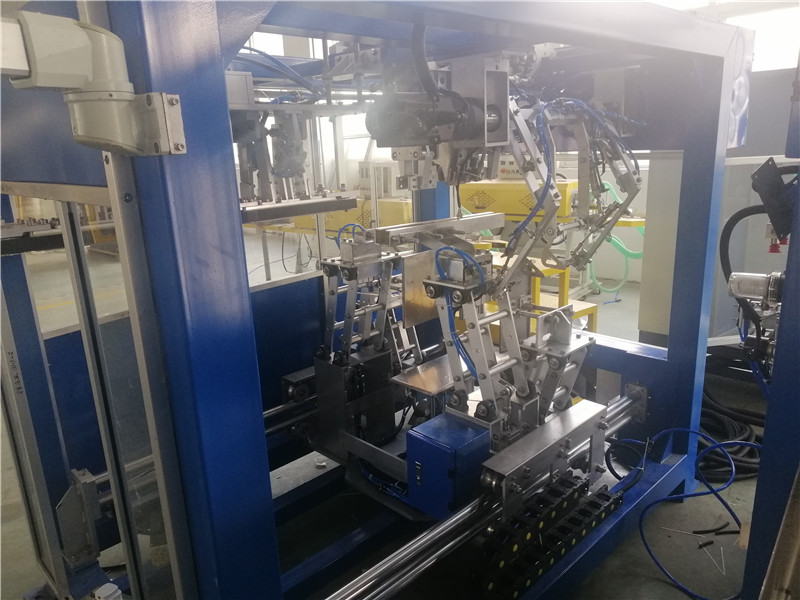

Factory Gallery

Processing Workshop

Mounter (Japan)

CNC machining center (Japan

CNC bending machine (USA)

CNC punch (Germany)

Laser cutting machine (Germany)

Baking paint production line (Germany)

Three coordinate detector (Germany)

Input software program (Germany)

Why Choose Us

Cooperation

Packaging & Transportation

FAQ

Q1. What is the advantage about your company?

A1. Our company has professional team and professional production line.

Q2. Why should I choose your products?

A2. Our products are high quality and low price.

Q3. Any other good service your company can provide?

A3. Yes, we can provide good after-sale and fast delivery.

Q4.What kind of Transportation could you provide?And are you able to update the production process Information in time after placing our order?

A4. Sea shipping, air Shipping, and international express. And after confirming your order ,we would keep you updated of production details of emails and photos.

Product detail pictures:

Related Product Guide:

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for 2022 Good Quality Hopper Bagging Machine - open mouth bagging system , Bagging System for 20kg to 50kg – Leadall , The product will supply to all over the world, such as: Qatar, South Africa, Senegal, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.