2022 Good Quality Hopper Bagging Machine - 20kg to 50kg Open Mouth Bagging Machine for Broken Corn, Corn Flour, Fine Corn Flour, Corn – Leadall

2022 Good Quality Hopper Bagging Machine - 20kg to 50kg Open Mouth Bagging Machine for Broken Corn, Corn Flour, Fine Corn Flour, Corn – Leadall Detail:

Details

Technical specification

| Name | Open mouth bagging machine |

| Bagging weight range | 20-50kg |

| Packing speed | 6-12bags/min |

| Bag Material | Width:400-520mm; length: 550-950mm |

| Air consumption | 1Mpa |

| Gas consumption | 2m³/min |

| Power voltage | 220VAC/380 three phase/50HZ |

| Power | 8Kw |

application

| Granule | Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, Polyester Chips, Polyester Flakes, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules etc. |

| Powder | milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, chemical powder etc. |

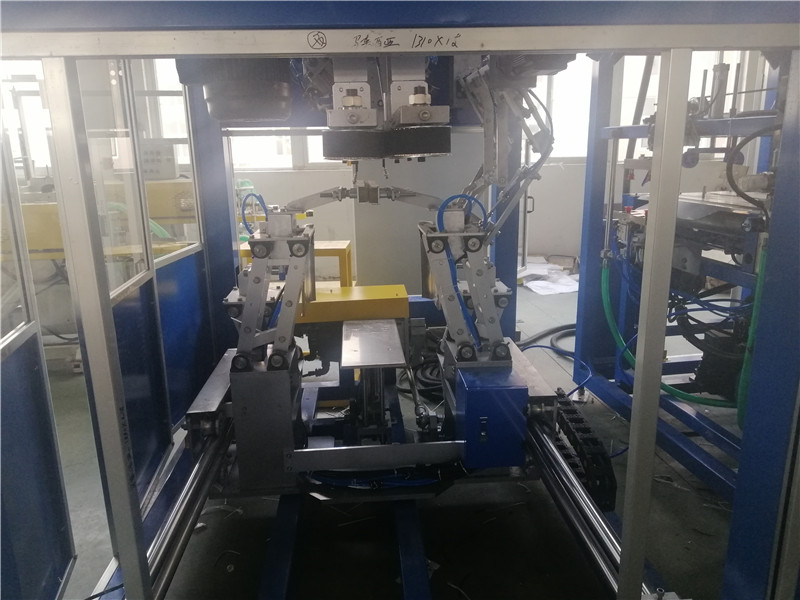

Main Structures

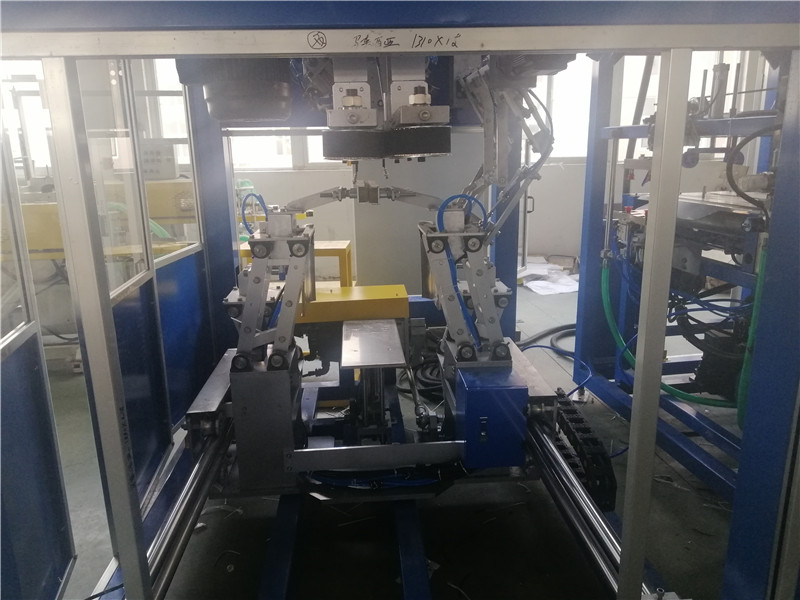

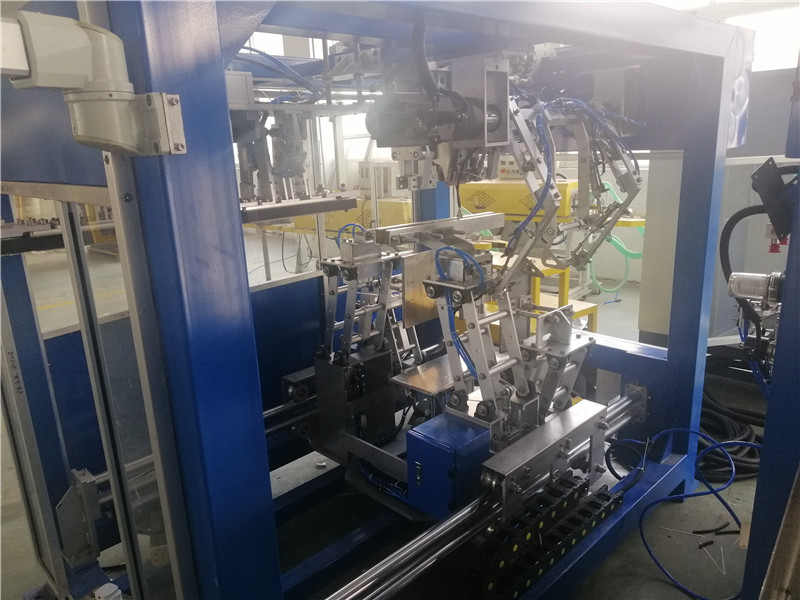

1. Auto bag placing

2. Auto filling system (belt feeder)

3. Auto weighting balance

4. Auto bag filled

5. Auto bag sealed

6. Electric control cabinet

Advantage

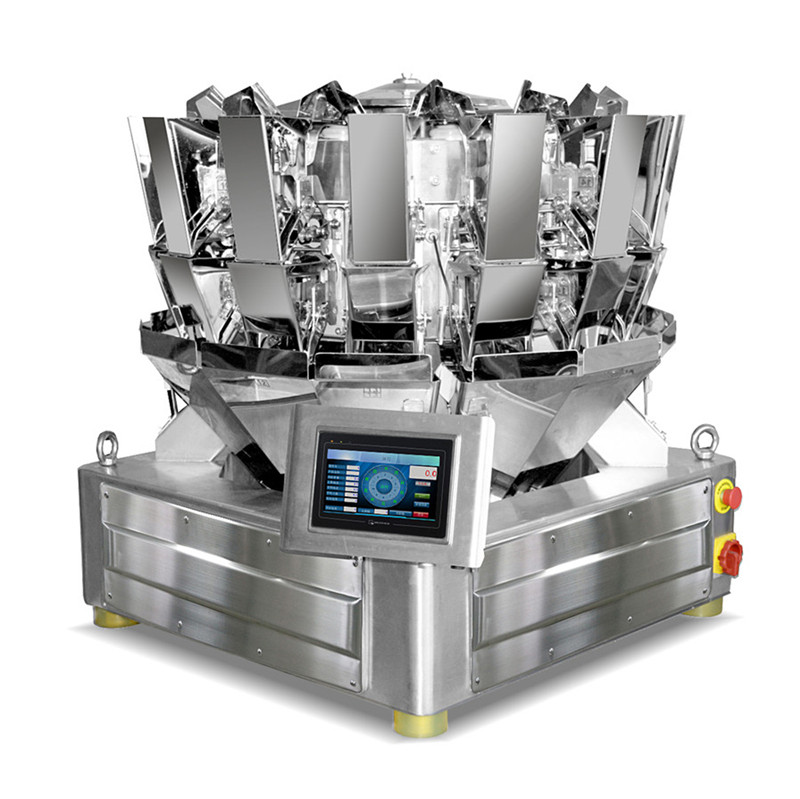

1. Dual Hopper Weighing System– with Mettler Toledo Brand Load Cell

2. Use France Schneider brand electric parts

3. Use Taiwan or Japan or Germany pneumatic parts

4. Provide all life online after sales service

5. Machine designed and manufactured based on 8 years+ life.

6. Fully automatic type, no need labor

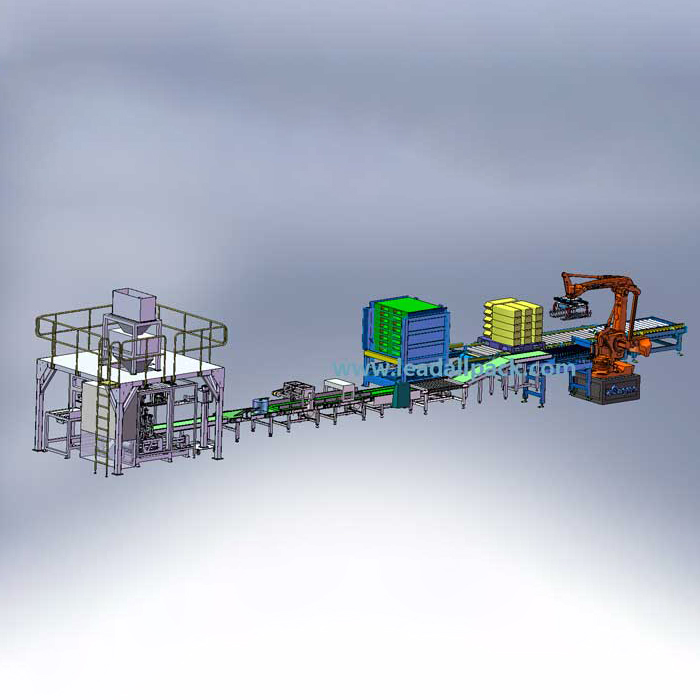

Whole Introduction for system

1. The system is suitable for paper bags, woven bags,plastic bags and other packaging materials, widely used in chemical industry, feed, food ,fertilizer and other industries.

2. Can be suitable for 20-50kg bag packaging, with up to max 1200bags/hour capacity.

3. Automatic bag device adapt to high-speed continuous operation.

4. The execution unites are equipped with control and safety devices,automatic continuous operation.

5. Using SEW motor drive unite can play higher performance.

6. Proposed matching KS series heat sealing machine work to ensure beautifual bag, anti-leakage, airtight.

Automatic packing machine process

1. Automatic for the bags–>2 aligned horizontally opposed bags disk can store about 200 empty bags( storage capacity due to the thickness of the air bag varies), take the bags from the suction cup device to a device for bags. When the empty bag after taking a unit, set the bag tray next unit automatically switches to take the bag position to ensure continuous operation of the device.

2. Bag–bit integer–>to adjust the overall position of the bag.

3. Empty bag extraction–>extraction bag bit plastic plate over the bag.

4. Lateral movement–>empty bag gripped by the clip below spout body bags, cutting open the door into the pouch feed.

5. Empty bag open–>empty bag after moving to the feed opening position, open the bag by the vacuum suction.

6.Bag feeding device–>empty bag gripped by the clip below spout body bags, cutting open the door into the pouch feed.

7. Transition hopper+secondary materials door–>hopper for the transition section between the weighing machine and packaging machines, the main function of the secondary material is next door from the slow process of material action to reduce air content material.

8. After the bag bottom slap device–>filling material, this means slap bottom of the bag, so that the bag material fully implemented.

9. Solid lateral movement and the bag holding the bag inductions–>real bags from the spout to put on stand -up pouches conveyor, by the bag holding means holding the bag delivered to the sealing.

10. Stand-up pouches conveyor–>real bags whereby the conveyor at a constant speed of delivery to the downstream, height–adjustable handle height adjustable conveyor.

11. Transition conveyor–>with different device height of perfect butt.

application

Packing

Product detail pictures:

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for 2022 Good Quality Hopper Bagging Machine - 20kg to 50kg Open Mouth Bagging Machine for Broken Corn, Corn Flour, Fine Corn Flour, Corn – Leadall , The product will supply to all over the world, such as: Thailand, Greece, Kenya, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!