2022 Good Quality Bulk Bag Filler Hopper - Polyester Chips Bulk Bag Filler for 500kg to 1200kg – Leadall

2022 Good Quality Bulk Bag Filler Hopper - Polyester Chips Bulk Bag Filler for 500kg to 1200kg – Leadall Detail:

Technical specification

| Machine Name | Bulk Bag Filler |

| Material range | 0.5-1.2ton |

| Packaging speed | 4-10 tons /hour |

| Accuracy | static accuracy 0.1%FA.OIMLⅢ grade, dynamic accuracy 0.3% |

| Powder Supply | AC380V |

| Air supply | 0.4-0.6 Mpa, 2 M3/H |

| Power | 2.5Kw |

| External dimension (LxWxH) | 5200x1800x3500 |

application

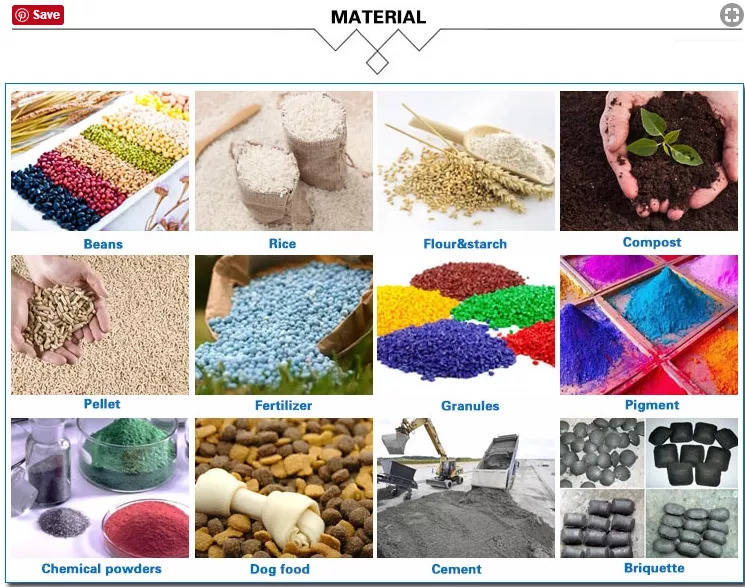

| Granule | Seeds, peanut, green bean, pistachio, refined sugar, brown sugar, PET food, Polyester Chips, Polyester Flakes, animal feed, aqua feed, grain, granular drug, capsule, seed, condiments, granulated sugar, chicken essence, melon seeds, nuts, fertilizer granules etc. |

| Powder | milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, chemical powder etc. |

Advantages

1. The weighing system of CJD1000K quantification Ton packaging machinery contains high accuracy(0.02%) sensor and high resolution controller, to keep the machine with high accuracy and stable performance.

2. The material feeding parts adopt two kinds (big one and small one)valves to control the three kinds feeding: fast, slow and exactness.

3. The packing range is 0.5~1.2 ton adjustable. It suitable to big bags packing.

4 .The parameters setting and the weighing calibration is very simple and with convenient operation.

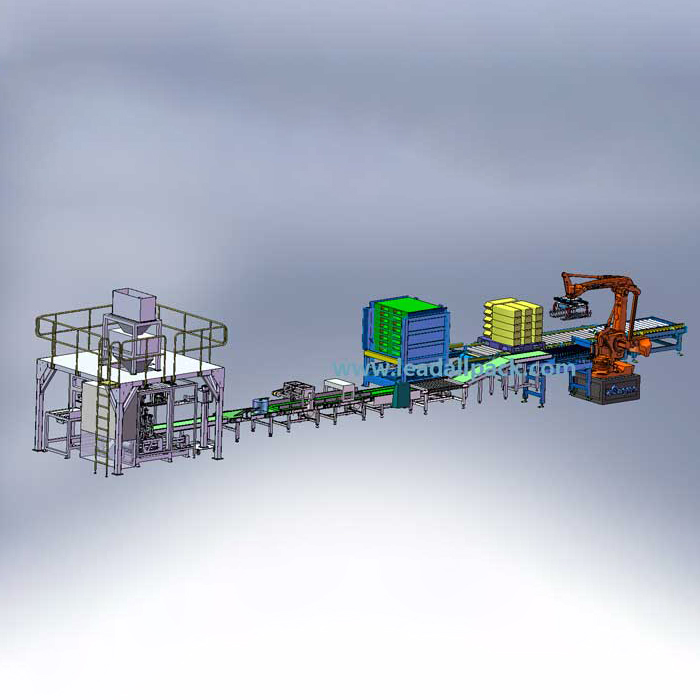

Construction Principle

1. Feeding part: Adopt two kinds(big one and small one)valves to control the three kinds feeding: fast, slow and exact mess.

2. Weighing shelf:The weighing shelf connected with sensor,and convey the weight signal to the electric box which controlling the operation of the machinery.

3. The electromotion car operated by the motor and run in the track to convey the products.The car’s position controlled by the worker and the final position is determined by the limit switch.

4. Electric box:Exterior signal and the sensor signal are conveyed to the electric box,which could control the feeding ON and OFF, cylinder lifting and the car running through finished program.

application

Other optional device

Packing

Product detail pictures:

Related Product Guide:

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is "You come here with difficulty and we give you a smile to take away" for 2022 Good Quality Bulk Bag Filler Hopper - Polyester Chips Bulk Bag Filler for 500kg to 1200kg – Leadall , The product will supply to all over the world, such as: Ecuador, Burundi, Jeddah, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.